Airborne Particle Counters (APCs) play a critical role in monitoring and maintaining the cleanliness of environments where air purity is essential, such as cleanrooms. There are two fundamental types of APCs: portable and fixed-point remote. Each type has unique features and applications, making them suitable for various scenarios in contamination control.

Portable APCs are self-contained units equipped with a user interface or operator panel that controls the instrument. These devices include a built-in sampling system and are easy to transport. The user interface allows users to establish sample parameters, collect data, and, if necessary, transmit this data to an external system. The air sampling system, whether a vacuum pump or blower, must also provide an adequately filtered exhaust system to prevent contamination of the test environment. Portable APCs can operate on internal batteries or via an AC wall outlet.

Types of Portable APCs

Portable APCs are differentiated by their airflow sample rates, which are reported in volume per minute in either Cubic Feet per Minute (CFM) or Liters per Minute (LPM). The main types include:

- Handheld APCs: These have low sample flow rates of 0.1 CFM (2.83 LPM) or lower. They are compact and convenient for quick checks.

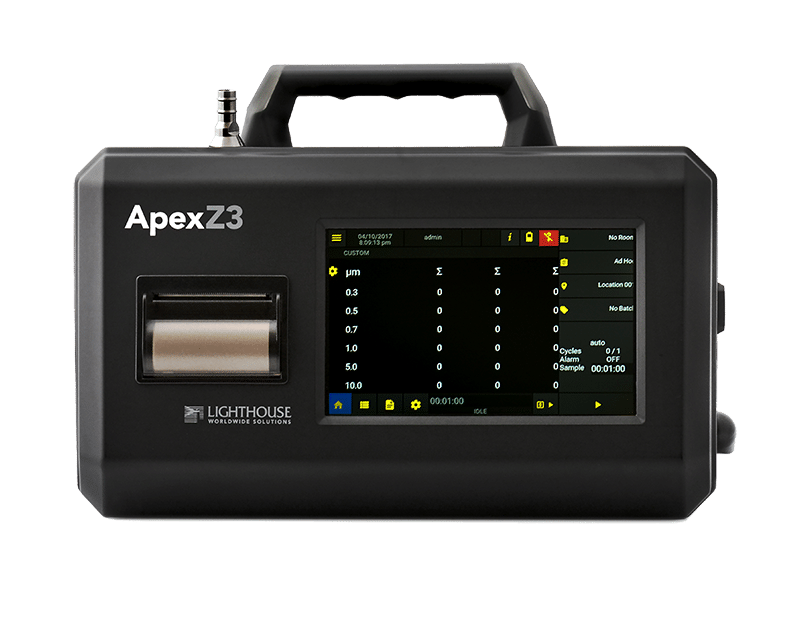

- Standard Flow Portable APCs (ApexZ3): With a sample flow rate of 1.0 CFM (28.3 LPM), these are the most common type used in general cleanroom operations.

High Flow Portable APCs (ApexZ50): These have sample flow rates greater than 1.0 CFM (28.3 LPM). Common high flow rates include 50 LPM, 2.0 CFM, 75 LPM, and 100 LPM. These high flow rate instruments are useful in cleanroom certification testing as they can sample large volumes of air quickly. For example, a high flow rate APC can sample one cubic meter of air in a Grade A environment much faster than a standard flow rate APC.

Fixed-Point Remote Airborne Particle Counters

Fixed-point remote APCs are smaller, less invasive, and more robust than portable APCs, allowing them to be attached to process equipment, cleanroom walls, or transport devices. They are ideally suited for monitoring critical process locations where product integrity may be at risk during manufacturing.

APCs typically have sample flow rates of either 0.1 CFM (2.83 LPM) or 1.0 CFM (28.3 LPM), with the latter being preferred for most applications. These devices can log data or transmit it to external systems such as Building Management Systems (BMS), Non-Viable Particle Monitoring Systems (NVPMS), or Facility Monitoring Systems (FMS).

Types of Remote APCs: There are two main types of remote APCs: those with built-in pumps and those without.

Remote APCs with Built-in Pumps: These units have built-in sample handling systems via pumps or blowers, along with the necessary filtration for all air exhausted from the unit. They are larger, louder, and more expensive than units without pumps but do not require a facility-wide vacuum pump and distribution system.

Remote APCs without Pumps: These units require an external vacuum source and are smaller, quieter, and less expensive than units with built-in pumps. They have lower service costs because there are no filters or small pumps to maintain. However, the supporting facility-wide vacuum pump and distribution system require regular service and must provide adequate flow and vacuum for the APCs to operate correctly. Some remote APCs have built-in flow monitoring to ensure correct air sample flow.

Conclusion

Understanding the different types of Airborne Particle Counters and their specific applications is essential for maintaining contamination control in cleanrooms and other sensitive environments. Portable APCs offer flexibility and ease of use for various applications, while fixed-point remote APCs provide robust, continuous monitoring solutions. By selecting the appropriate type of APC, facilities can ensure they meet stringent cleanliness standards and maintain a contamination-free environment.

Curious to Know More?

To see all the Airborne Particle Counters we offer visit this page.

To learn more about the applications of Airborne Particle Counters visit this tech paper.