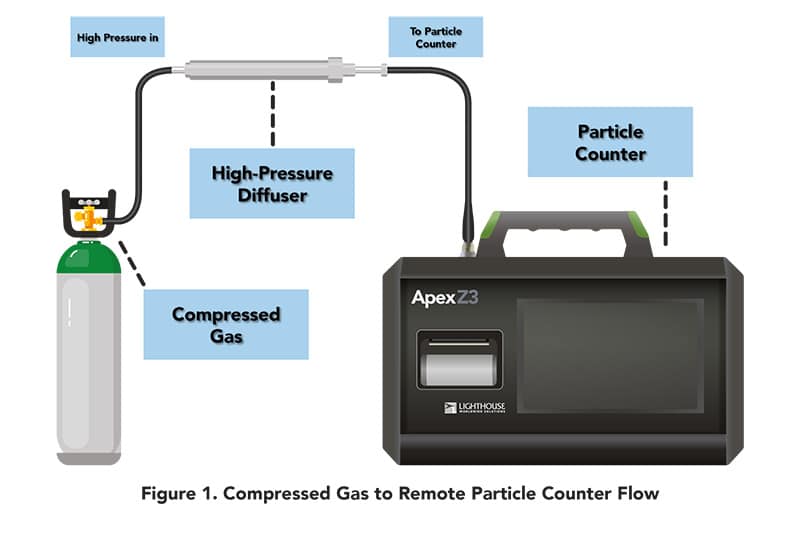

According to ISO 8573, particle counters are an acceptable testing method for compressed gasses with a few guidelines. The particle counter must maintain isokinetic sampling. This is a sampling technique that prevents skewed particle concentration measurements as they enter the sampling nozzles. Particles can often be skewed due to inertia but using a high-pressure diffuser to change the pressure allows the gas stream to maintain the same velocity throughout the entire testing process. This provides a more accurate measurement of concentration.

To maintain isokinetic sampling while using a particle counter, ISO 8573 requires you use a high pressure diffuser (HPD). There are two primary types of HPDs: Vented Return HPDs and Ported Exhaust HPDs. Which HPD you choose depends on the type of compressed gas you are using. Vented Return HPDs vents the gas back into the environment, whereas Ported Exhaust HPDs releases the air outside of the environment. This is useful for unsafe gasses, such as flammable ones if open flames are present in the environment.

If you use the right Active Air Sampler, it can eliminate the need for attachments like an HDP. For example, the Lighthouse’s ActiveCount100H makes gas sampling a breeze. You’ll need to start with a new Petri dish, free of agar. Once the fan is blowing, you’ll attach the gas sampler snugly in the sampling head. Next, you’ll simply adjust the flow rate to optimize it for gas sampling. If you need to test for viable contamination, you will need to use an active air sampler. Particle counters are able to tell you the number and size of particles, but not the type. Viable particles are able to grow and multiply, so it can be important in certain application to know if you are dealing with viable particles. See video below.