Your Environmental Monitoring System stands between you and system failure, product recalls, contamination, and potential lawsuits. Sounds intense? We think so, too. But as the world’s clean air experts, we know it can be done right so at the end of the day you save time, money, and stress. Today, we’ve outlined the steps you can take to ensure you’re properly choosing and installing an Environmental Monitoring System.

What Is An EMS?

An Environmental Monitoring System is made up of various environmental sensors used to monitor critical locations in a cleanroom. These sensors can include (but are not limited to) particle counters, air sampling devices, temperature, humidity, and pressure sensors.

An effective EMS collects real-time data so it can work as an early detection system for contamination in a cleanroom. It’s the frontline of your contamination control strategy! Because it is so important, it’s critical to know that you have a system that is working for you instead of against you.

So how do you make sure that you are choosing the right EMS?

Know Your Specifications & Needs

First and foremost, you need to know your specifications. What do you need out of the EMS? The best place to start is by asking questions about your cleanroom, contamination control strategy, and organization.

No need to worry – we’ve compiled a comprehensive list of questions to get you started on knowing what you need from an EMS.

● Where will you want to see and process the EMS data?

● Will the monitoring system be a closed system, i.e. not operating on your local area network (LAN)?

● Will the EMS data need to be viewed and archived across your LAN?

● Can the monitoring system be a closed system and operate across your LAN at the same time?

● Will you allow external sensors to be installed?

● Can you install EMS Clients on your LAN?

● What operating systems are supported?

● What are your needs or policies regarding data storage and back-up or archiving?

● How do you configure a Mirror database and where is the best place to put it?

● What is your appetite for risk?

● Is a real time hot standby monitoring system needed?

● Do you need or want redundant monitoring system?

● Is there a site UPS available? What do you want it connected to?

● How much redundancy do you need? Is it practical?

● Is the data 21cfr11 compliant?

● How many Remote Particle Counters do you want to connect to the system network?

● Can you integrate remote Particle Counters into the system network?

● Can you integrate environmental sensors into the system network?

● Can you connect alarm beacons into the system network?

● What is the maximum number of sample points or sensors supported by the Monitor and Client?

● What is the minimum sample interval?

This list of questions is a jumping off point to ensure that you know what you need from an EMS. But these questions can also be overwhelming – especially when it comes to the point of strategizing how to make the most of your EMS. No need to worry, though, because there are professionals who can walk you through this process and make it a breeze.

Choose Your Type Of EMS Network

Once you know what you need from an EMS, it’s time to choose your time of network. There are three main types of networks: stand-alone, distributed, and complex distributed.

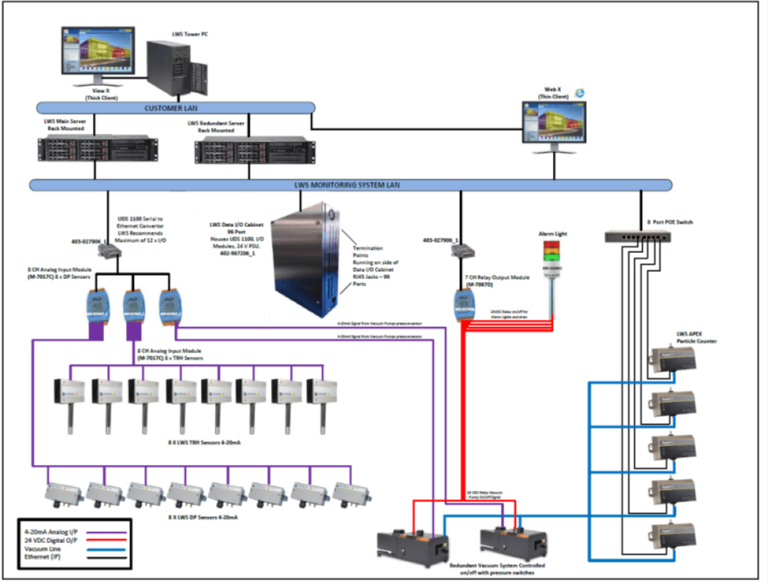

Stand-Alone Network

Stand-alone networks are commonly used with vacuum redundancy in medium sized monitoring systems. We see them a lot in hospital pharmacies and pharmaceutical filling lines.

With this type of network, your Local Area Network (LAN) is not used. Instead, it uses its own network. This makes it easier for your IT to support it and is the most secure and simplistic network.

But if validation is a priority, we’d recommend a more complex system.

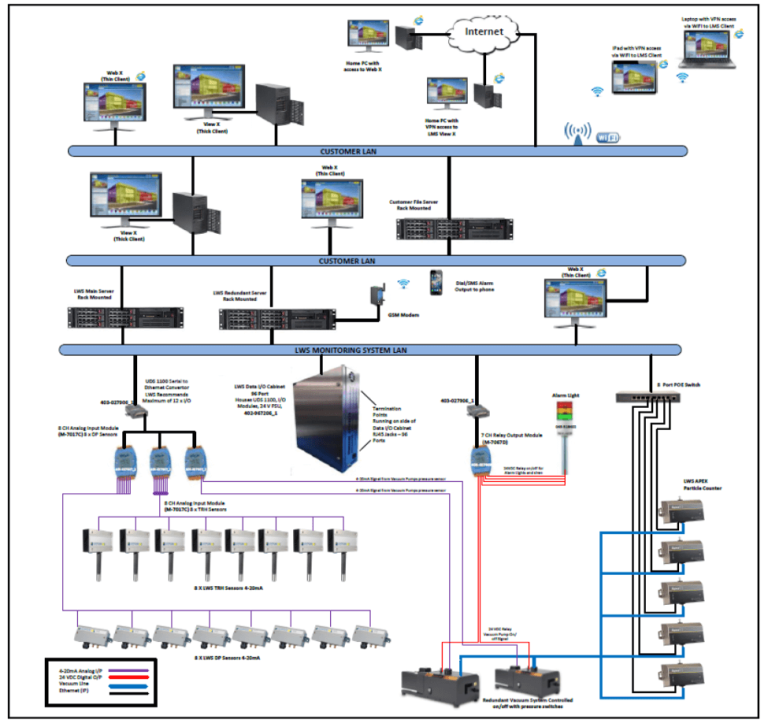

Distributed Network

We see distributed networks in medium to large sized facilities where system up-time is the priority and data loss cannot be tolerated. This network uses your LAN to make data available to users and archive critical data.

Since this is a more complex network, it works well for organizations that need more features and functionality from their Environmental Monitoring System (EMS). But this does make it more difficult or impossible for local IT to manage. All this means, though, is that you want to get an EMS from a company willing to develop a relationship with you and stay involved.

Complex Distributed Network

This is the most complex type of network for EMS, so it is most commonly used in large cleanrooms, specifically pharmaceutical facilities. They are most useful when there are a number of manufacturing processes. They are usually on the same site but in different buildings.

This type of network does require professional installation in conjunction with local IT, as it requires exhaustive validation. Because of the complexity, the network relies on your LAN to facilitate system access and control.

Plan Your Installation

Now that you know what you need from an Environmental Monitoring System and what type of network would be optimal to run it on, you need to plan your installation! The actual installation of an EMS is easiest when you have all your ducks in a row before you begin. The perfection and effectiveness of an EMS lies in the details – and the details start in the drawings, down to the height of the wall plates.

The good news is that you don’t have to plan this installation. We offer comprehensive installation services for Environmental Monitoring Systems, where we walk you through exactly what you need, what will be most effective, and then install it for you. We’ll work with you to optimize the process from start to finish, because once physically installed, changes become costly.

So let’s talk about what we’d cover for you in the installation process and what you need to know about choosing your construction type.

Choose Your Construction Type

There are two types of walls we mainly use when constructing around an EMS: partition walls and sandwich panels. Both will be constructed out of cleanroom grade and safe materials that are easily sanitized.

The tricky thing about choosing your construction type is that you might end up competing with other utility services that use the same routing and wall space. Keep that space in mind when considering your options.

Partition Walls

With partition walls, cables and tubing are easy to install as long as they are routed before the final places are put into position.

Sandwich Panel

An alternative construction option are sandwich panels, which are the most common choice in new builds. Cables and tubing can be run down a channel between two panels then are finished out.

The neat thing about sandwich panels is that the ceiling can be made from the same material!

Run Tubing And Cabling

The next step in the construction process is to actually run the tubing and cabling. This will need to be run through whatever type of wall you choose. Once these are in place, they are extremely costly to move, so this is where the detailed plans come into place. Additionally, if installed incorrectly, your EMS will not be as effective.

Install Sensors

Last but not least, it’s time to install the sensors. These are the fundamental components of the Environmental Monitoring System so choosing them should not be taken lightly. Their placement is critical, as well. But – no worries – because you can have the professionals take care of this for you.

Choose An Expert To Install Your Environmental Monitoring System

Choosing the wrong EMS could result in product contamination, costly delays in production, product recalls, and more. Not to mention the cost of installing a different system once it becomes apparent that one is not working.

So do it right from the beginning.

Work with a company that stands by its products, walks with you from start to finish, asks all the right questions, and has been setting industry standards for more than 40 years. Our clean air experts are ready to take on your project and give you the peace of mind of knowing that you’re doing what is best for your cleanroom.

Want to start getting your EMS squared away? Email Us today