Air particles are measured by forcing air through a cavity in a particle counter which uses a laser to measure and count the particles. This is done through a process called light scattering.

Parts Of A Particle Counter

Inside a particle counter, you will find a laser sensor block. This is where the particles are sized and counted using a process called light scattering. The laser sensor block is made up of:

● Sensor housing- Is the actual part of the particle counter that contains the sensor.

● Laser diode- This is where the laser emanates from to count the particles.

● Sample inlet- Particles are drawn in through the sample inlet, typically by an artificial vacuum.

● Sample exhaust- Particles exit through the sample exhaust.

● Sample view volume-The area where particles pass through the laser and scatter light.

● Photodetector-The photodetector is what determines the size of particles passing through the laser by detecting the intensity of light scattered.

How Light Scattering Works

So how do all those components come together to count and size particles? The particles are pulled in through the sample inlet and pushed into the sample view volume, in front of the laser diode. As the particles pass through the laser, the photodetector determines the size of particles by how much light the particle scatters. The laser’s reflection onto the photodetector changes when a particle blocks it. The photodetector gives you an electrical signal based on the amount of light scattered.

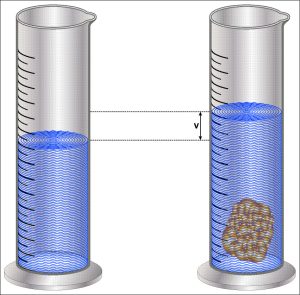

This is the basic physics of volume. If you had a 5-gallon bucket of water that was only filled halfway, then dropped a bowling ball in it, the water level would rise. You would be able to determine the size of the ball using a basic physics formula.

Light scattering works the same way: the particle displaces the laser and the photodetector determines the number and size based on the displacement.

Types Of Particle Counters

So what kind of airborne, light scattering particle counter is right for your cleanroom?

Handheld Particle Counters

Handheld particle counters are easily moved because they’re very small. So if you are in the process of classifying your cleanroom, they are very useful for handheld spot checks. They usually have a localized display on them, so you don’t have to leave the room to see the results. But this does not limit connectivity, as they often still have connectivity and data organization options.

Handheld particle counters are also widely available and relatively affordable. They have added bonuses, like reading temperature and air humidity.

But there are drawbacks to using a handheld particle counter. Since they are small, they do not force airflow, thus readings can take longer to produce. But they really are designed just for spot checks, which means they don’t work well as a permanent particle counting solution and they don’t integrate well with real-time systems.

Remote Particle Counters

Remote particle counters are designed to be integrated into a room and then stay there, so they’re not easily moved. They do continually send readings to outside sources, which means they don’t have localized displays usually. So if you need to know the reading while you are in the cleanroom, you may need to leave the room or communicate with someone outside.

But they are usually very small and designed to fit seamlessly into the cleanroom while being an affordable option. They offer tons of integrations so they build into an established system relatively easily. Along with integrations, they offer a wide variety of communication options.

So if you have a larger, stationary system with the space and infrastructure external vacuum and are willing to create a network of particle counters, a remote particle counter set-up might be right for you.

Portable Particle Counters

Last but not least, there are portable, light scattering particle counters. These are the largest option, but more mobile than a remote particle counter and more versatile than either other option.

While being a more expensive option because of the flexibility and adaptability, the portable particle counter is ideal for classifying a cleanroom. They are designed to create a vacuum AND be highly accurate and mobile. Their vacuum creates one of the highest airflows of all particle counters, so they have a quicker volume sampling. The localized display makes it possible to see the reading without leaving the cleanroom, too.

Similar to the remote particle counter, portable particle counters are designed with connectivity and data organization at the forefront. Physically, they are user-friendly and ergonomic. Their flexible usage allows them to be used all over the cleanroom.

Unlike remote particle counters, portable particle counters do not require established infrastructure, but they do offer options to integrate with pre-existing systems. But, best yet, there is minimal set-up involved.

What Is The Best Particle Counter For Your Cleanroom?

Depending on the size and use of your cleanroom, several options could be right for you. If you just need to spot-check without reliable monitoring, then a handheld particle counter could be the right choice for you.

But in larger cleanrooms that are continuously used, we tend to recommend a remote particle counter or a portable particle counter, like our Apex Z.

The Apex Z is quiet, easy to clean, and highly ergonomic, so just about anyone in your cleanroom can use it. Not to mention, the Apex Z has the largest battery life and shortest recharge time on the market.

With programmable SOPs, traceable GMPs, self-diagnostics, integrated alarm light, and simple connectivity, the Apex Z is designed to integrate seamlessly into almost any cleanroom.

But if a portable particle counter isn’t right for your cleanroom, we have many solutions. For a hassle-free consultation about what is best for your cleanroom, give us a call.