Air Sampler impaction technology has been around for decades. However, the d50 is a little known aspect of air sampler technology design and it plays a critical role in air sample capture.

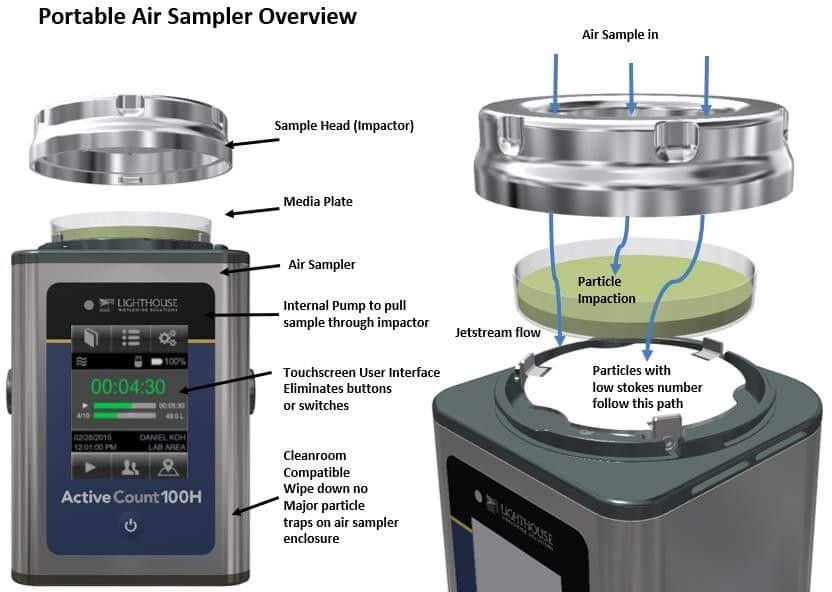

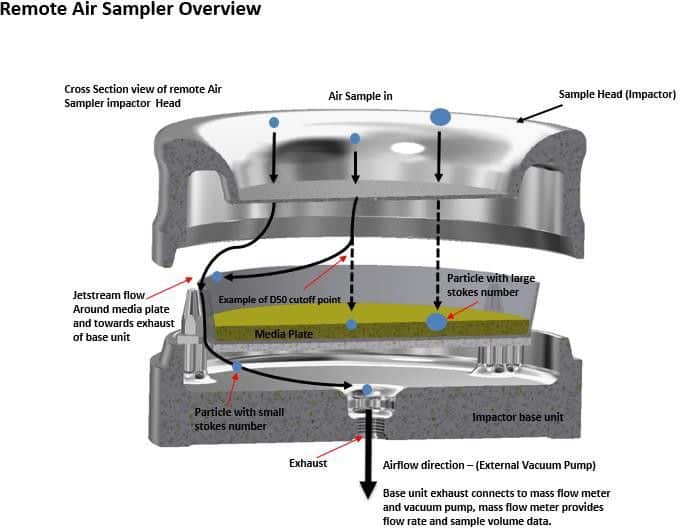

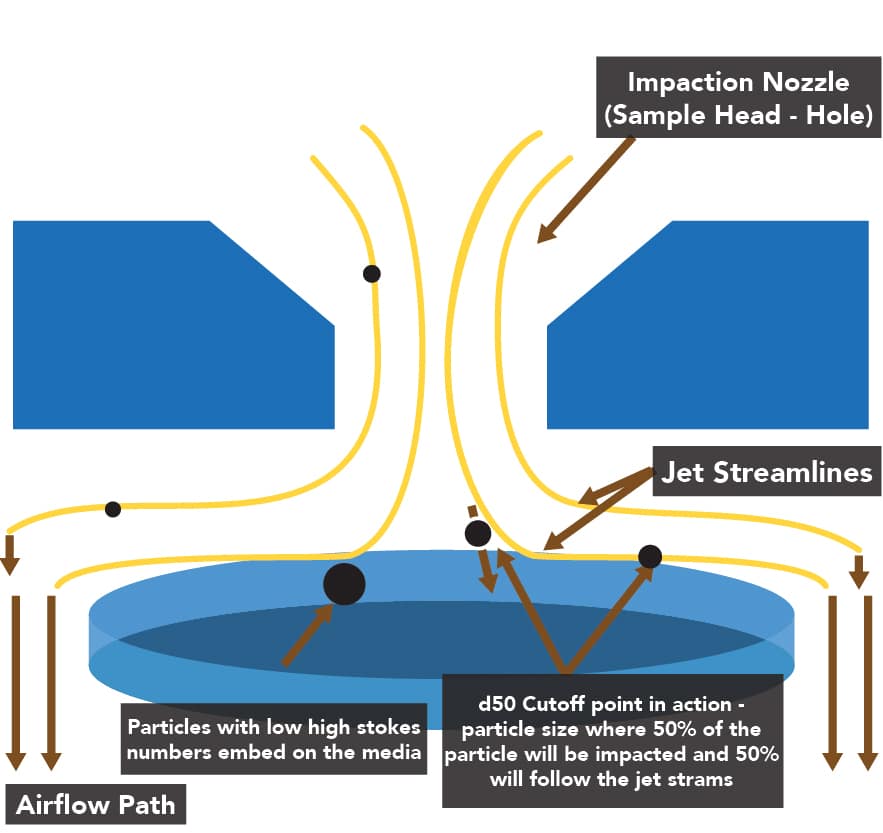

Aerosol Impaction is the process in which particles are removed from an air stream by forcing the gases to make a sharp bend. Particles above a certain size possess so much momentum that they cannot follow the air stream and strike a collection surface such as a media plate which is available for later analysis of composition after an incubation period.

One of the most fundamental selection criteria for an Air Sampler is the resolution of the Air Sampler which can be equated to the d50 cutoff point. We all know with a particle counter it must count 0.5um and 5.0um particles as a minimum. The same holds true for an Air Sampler and its ability to capture particle sizes of interest, especially when single rod bacteria diameters are as low as 0.3um in diameter, it becomes such a critical factor in selecting an air sample with the right d50 (Resolution) and the ability to collect the smallest particle size physically possible.

What is the d50 cutoff point?

Aerosol Impaction Air Samplers that have a “sharp cutoff” approach the ideal step-function efficiency curve, in which all particles that are larger than the designs cutoff diameter (aerodynamic size) strike a collection surface or media plate and all particles smaller than the cutoff diameter pass through. When operated at the design flow rate, all particles larger than the cutoff diameter will possess enough momentum to separate from the nominal flow and collide with the collection surface or media plate.

The d50 cutoff point/size for an Aerosol Air Sampler is the size at which 50% of the particles will impact the collection surface or media plate while 50% stay in the nominal air flow and are not collected; the d50 cutoff size is one of the fundamental metrics for evaluating and selecting an Air Sampler, and can be thought of as the resolution of the device. The d50 size of an Air Sampler is analogous to the 50% channel on a particle counter, and is a measure of the smallest particle size that can be physically captured by the Air Sampler.

It is important to understand that not all Air Samplers have the same d50 cutoff point/size, and it is also helpful to understand the dominant variables that are involved when calculating an Air Sampler’s d50. . We all understand that a Particle Counter used widely in Environmental Monitoring programs has a set 50% channel size based on the smallest particle size it can physically detect (with 50% Count efficiency). The same holds true for Air Samplers as they have a limitation on the size of particles that will impact on the media.

What is the resolution of Lighthouse Air Samplers and how is the d50 calculated?

The main contributors to an Air Sampler d50 are;

Impactor Geometry – number of holes, diameter, flow area, Flow Rate – nominal flow rate and flow through single hole

Impaction velocity – jet velocity onto media plate (function of Impactor Geometry and Flow Rate) Temperature– of air/gas being sampled (air/gas viscosity is primarily a function of temperature) Particle Density– assumed to be 1000 kg/m^3

Lighthouse Air Sampler d50 values have been calculated based on the following formulae and have a d50 between 0.97µm and 1.1 µm meaning that its collection efficiency meets the requirement of ISO 14698 recommendation of at least 1µm. EN 17141 recommends below 2µm. This ensures that the Lighthouse range of air sampler products are ideal for cleanroom and controlled environment applications. This resolution of Lighthouse Air Samplers means that particles at 1um and above will be captured onto the media and thus can be incubated. Lighthouse Air Samplers have the sensitivity to reliably capture viable contamination at sizes expected in cleanroom and controlled environments.