If you have ever had a shot or used a cellphone, you have relied on a liquid particle counter! Liquid particle counters are used to measure the size and volume of particles in a sample of ultrapure water used in cleanrooms.

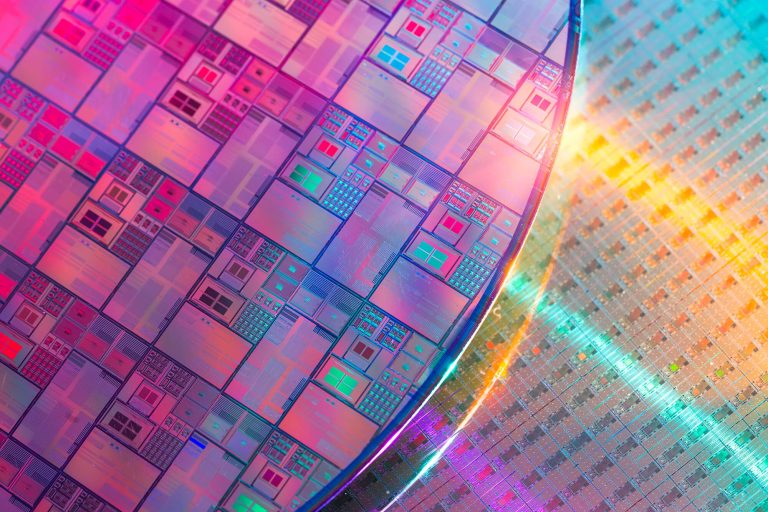

Ultrapure water is water that has been specially processed to minimize contamination. It is used for the production of water for injectables (WFI), semiconductors, and other processes that require water in cleanrooms. Semiconductors and WFI are particularly regulated industries, with semiconductor guidelines being outlined by the International Technology Roadmap for Semiconductors (ITRS) and the FDA regulating ultrapure water used for WFI.

In the case of semiconductors, contamination can prevent the end product from working correctly. This can present yield loss or, worse yet, recalls and public image damage.

On the other hand, contamination in WFI can result in death of the end user if it is not identified.

Thus, liquid particle counters are crucial for the functioning of a cleanroom that uses ultrapure water!

How Do Liquid Particle Counters Work?

Liquid particles work similarly to airborne particle counters, but with a few key differences.

They, too, pull in a water sample to be examined. While most airborne particle counters use light scattering, a liquid particle counter could use either light scattering or light blocking.

Either way, the sample volume of water is passed in front of a laser. The way the light is offset determines the number and size of particles. But let’s break down precisely how light scattering and light blocking works – and what the major difference is.

Light Scattering

In light scattering, the volume of sample water is passed in front of a highly focused laser. The laser is reflecting onto a photodetector. Because the laser is focused, any offset of the laser is recognized by the photodetector. The machine is then able to process the results and determine the number and size of particles – even the tiniest particles – and deliver the results to the technician. This is considered the gold standard in liquid particle counting and is used when precision is necessary.

Light Blocking

Light blocking is still accurate, but less precise for smaller particles. Instead of using a very focused laser, it uses a general light source. The photodetector does not recognize the offset of the light but, instead, the shadow the particle casts. This means that light blocking is less effective for smaller particles. Thus, light blocking is used in facilities where bulk is counted over precision and the detailed analysis of the water is not as crucial, such as water processing plants.

What Should You Look For In A Liquid Particle Counter?

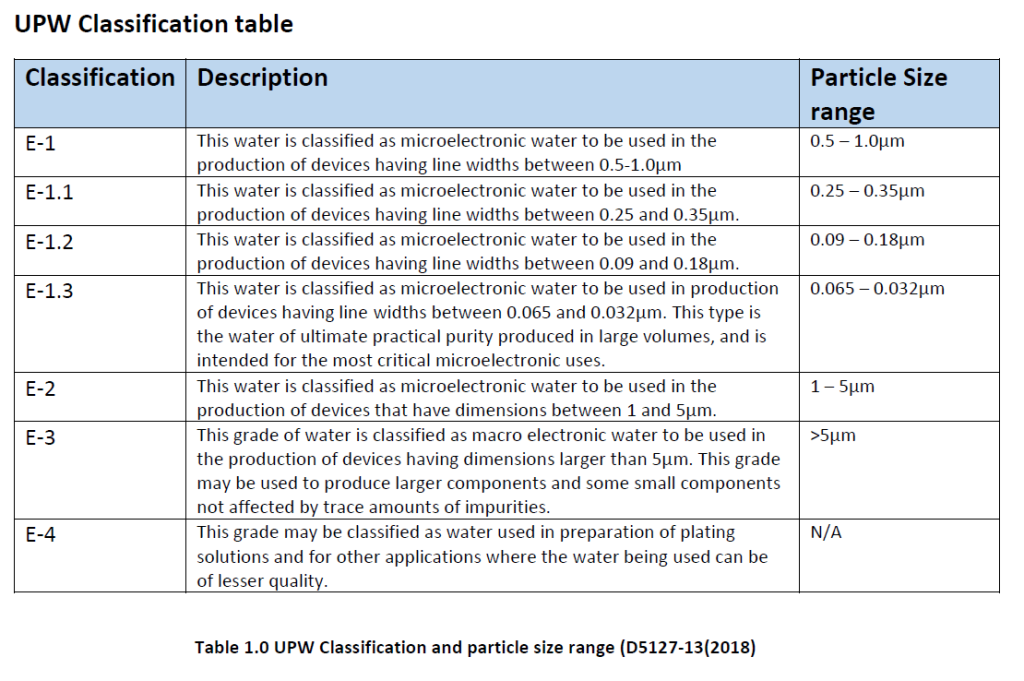

First things first, you need to know the regulations around what you are using the liquid particle counter for. For example, ITRS’s 2015 update specifies UPW should contain fewer than 1000 #/L (particles per liters), (1 #/mL (particles per milliliters)) at point of entry (POE) amongst other requirements. The following table outlines the particle size range for each classification depending on your line widths.

For the pharmaceutical industry, the United States Pharmacopeia outlines different types of water and their requirements: Bulk Purified Water, Bulk Water For Injectables, and Bulk Highly Purified Water. These waters have different uses in a cleanroom but all require strict monitoring using a liquid particle counter.

So, depending on your use, you will need to look for different specifications in a cleanroom. But a few outstanding measures remain the same:

- As with everything you use in your cleanroom, your liquid particle counter should be built from easily cleaned and sanitized materials.

- You need a liquid particle counter that has an excellent optic signal to limit cosmic ray noise.

- An ideal liquid particle counter has multiple particle channels so you have versatility.

- We recommend options for integration into a real time monitoring system for immediate alerts and mitigated yield loss.

- If you need to detect nanometers, you will need a liquid particle counter with a partial stream laser. With full stream lasers, a nanometer particle would not offset the laser enough to get a true reading. So you need a liquid particle counter that:

- Addresses laser safety standards,

- Reduces noise levels,

- Mitigates false count errors,

- And eliminates count correction algorithms.

Essentially, this means the laser technology needs to be completely re-examined to detect the smaller particles. This requires advanced detector technology with reduced flow cells and more intensity. This means that not all of the sample will pass through the laser at its highest intensity.

This is the foundation for partial stream laser technology. Traditional lasers are brightest in the centers, so particles that do not pass through the center of the laser won’t size correctly or scatter light sufficiently. They won’t be accurately detected. Thus, there is a tradeoff for nano size particle detections. The sensor has to has to be designed for partial stream detection, though they will not have the same counting efficiency expectations as full stream laser liquid particle counters. But the laser power to operate a nano detection sensor would be so powerful, the cost of the liquid particle counter would be too high with astronomical maintenance. Not to mention, current laser safety standards would be completely disregarded. Partial stream technology is the answer.

The good news is that there is a liquid particle counter that checks all the boxes with ease and leads the industry. With the lowest zero count levels and integrated manual flow, the Vertex 50 is the smallest and lightest 50nm liquid particle counter on the market. Based on state-of-the-art technology, it is backed by a two-year warranty and international support.

If you want to schedule your hassle- and obligation-free consultation, contact us today.