In the world of cleanrooms, where the highest standards of cleanliness and contamination control are paramount, air filtration systems play a pivotal role. The evolution of these systems, especially with the integration of advanced features, has significantly improved compliance with stringent industry standards. In this blog, we delve into the intricacies of these advanced air filtration systems, exploring how they are redefining the standards for cleanroom environments.

Understanding the Basics: What is a Cleanroom?

A cleanroom is a controlled environment where pollutants like dust, airborne microbes, and aerosol particles are kept at extremely low levels. These environments are essential in industries where small particles can adversely affect the manufacturing process. They are widely used in semiconductor manufacturing, biotechnology, pharmaceuticals, and more.

The Heart of Cleanrooms: Air Filtration Systems

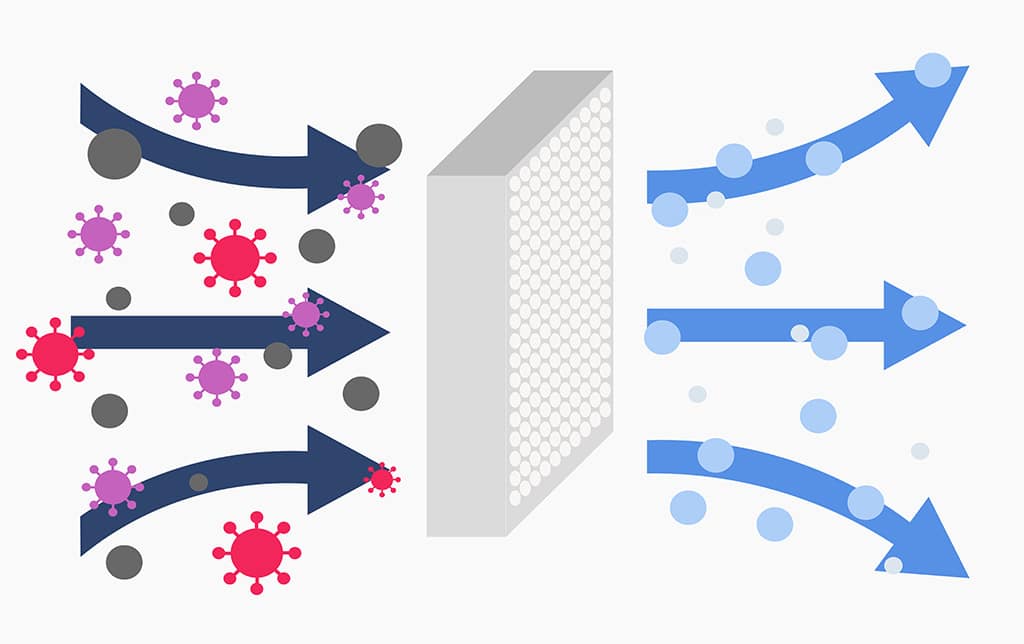

The key to maintaining the stringent cleanliness required in a cleanroom is an effective air filtration system. Traditional systems use High-Efficiency Particulate Air (HEPA) filters to trap particles as small as 0.3 microns. However, with the advent of more sensitive processes, the demand for even more advanced filtration systems has grown.

Advanced Features in Modern Air Filtration Systems

- Ultra-Low Penetration Air (ULPA) Filters: These filters can trap particles as small as 0.12 microns, making them more efficient than traditional HEPA filters. ULPA filters are becoming increasingly common in industries requiring ultra-clean environments.

- Ultra-Low Penetration Air (ULPA) Filters: These filters can trap particles as small as 0.12 microns, making them more efficient than traditional HEPA filters. ULPA filters are becoming increasingly common in industries requiring ultra-clean environments.

- Smart Monitoring and Control Systems: The integration of IoT (Internet of Things) technology allows for real-time monitoring and adjustment of filtration systems. This feature ensures consistent air quality and alerts maintenance teams to potential filter issues before they become problematic.

- Automated Particle Monitoring: Advanced systems are equipped with sensors that continuously monitor particle counts. This automation helps in maintaining compliance with industry standards and reduces the need for manual testing.

- Energy Efficiency: Modern air filtration systems are designed to be energy-efficient, reducing operational costs. They often include variable speed fans and energy recovery systems, which adjust airflow based on the cleanroom’s occupancy and contamination levels.

- Antimicrobial Coatings: Some advanced filters come with antimicrobial coatings to prevent the growth of bacteria and fungi on the filter surface, further reducing the risk of contamination.

The Role of Advanced Air Filtration in Compliance

Compliance with industry standards, such as ISO 14644 and EU GMP, is non-negotiable in cleanroom environments. Advanced air filtration systems ensure that these stringent requirements are not just met but exceeded. By providing finer filtration, real-time monitoring, and energy-efficient operation, these systems offer a level of control and reliability that was previously unattainable.

The Future of Cleanroom Air Filtration

The future of air filtration in cleanrooms is geared towards even more automation and smart technologies. We can expect developments such as AI-driven predictive maintenance, which can forecast filter lifespan and schedule replacements without human intervention. Additionally, there is ongoing research into new filter materials that could provide even higher levels of filtration efficiency.

Conclusion

The advancement in cleanroom air filtration systems marks a significant leap in ensuring the highest standards of cleanliness and compliance. As these systems continue to evolve, incorporating smarter, more efficient technologies, they will play an even more critical role in industries where the smallest of particles can have a significant impact. The future of cleanroom environments is not just about maintaining standards but setting new benchmarks for purity and efficiency.