Cleanrooms are essential controlled environments used in industries such as pharmaceuticals, biotechnology, and electronics manufacturing. Their primary purpose is to maintain high levels of cleanliness and minimize contamination, which is critical for ensuring product quality and compliance with stringent regulations. Recent advancements are providing fresh insights into how we can enhance cleanroom efficiency, and companies […]

Ultra Pure Water (UPW) is critical in industries where even the smallest impurities can have significant consequences. It is used in semiconductor manufacturing, pharmaceuticals, and high-end laboratories—applications that demand the highest level of purity. Achieving and maintaining this purity requires a complex process and advanced monitoring tools. This blog explores the UPW process and highlights […]

At Lighthouse Worldwide Solutions, we’re excited to introduce our latest innovation: the ActiveCount Remote Impactor Kit. This advanced system pairs the trusted performance of our ActiveCount25H or ActiveCount100H viable samplers with the newly developed Remote Impactor Kit. Designed specifically for cleanrooms and aseptic environments, this solution offers unmatched portability and flexibility, making sampling easier, even […]

Liquid particle counting is essential for maintaining public health and safety by monitoring the purity and quality of liquids across various sectors, including drinking water, pharmaceuticals, and food production. This technology helps detect contaminants that could pose health risks, ensuring that products meet strict safety standards and protect consumers. Protecting Drinking Water Quality A key […]

It’s actually not as complicated as it might sound at first. Think of GAMP as your friendly neighborhood guide to making sure medicines are top-notch and safe for everyone. GAMP stands for Good Automated Manufacturing Practice. It’s like a rulebook created by a group of pharmaceutical experts who want to make sure that when we use […]

In the world of cleanrooms, where the highest standards of cleanliness and contamination control are paramount, air filtration systems play a pivotal role. The evolution of these systems, especially with the integration of advanced features, has significantly improved compliance with stringent industry standards. In this blog, we delve into the intricacies of these advanced air […]

The 2022 update of the EU GMP Annex 1 has placed significant emphasis on the concept of continuous environmental monitoring (EM), highlighting it as a critical component in reducing the risk of contamination during the manufacture of sterile products. This shift towards continuous EM requires manufacturers to adopt specific techniques and align their monitoring programs […]

Compliance with USP 788 standards doesn’t have to be a complex and laborious process. Recent advancements in liquid sampling technology have made achieving USP 788 compliance both simple and effective. Liquid sampling plays a crucial role in contamination control strategies, ensuring that particulate contaminants are kept out of injectable pharmaceutical products and, ultimately, the bodies of end-users. […]

In the complex landscape of pharmaceutical manufacturing, where the safety and efficacy of medicinal products are paramount, Annex 1 of the EU Guidelines for Good Manufacturing Practice (GMP) for Medicinal Products 2022 stands as a crucial document. One of its core components, the Contamination Control Strategy (CCS), plays a pivotal role in ensuring the production […]

Your Contamination Control Strategy (CCS) is the foundation of your cleanroom. This is where you plan how to avoid contamination, what to do in the event there is a breach, and prove that you have done your homework. For too many years, a CCS has been an afterthought. The cleanroom was developed, protocols put in […]

The European Union (EU) Good Manufacturing Practice (GMP) for Medicinal Products for Human and Veterinary Use – Annex 1, commonly referred to as GMP Annex 1, released a new update in 2022. At the time of publishing, we have not yet seen updates in the United States, but should expect to see similar guidelines published […]

In 2020, a vote found EN ISO 14698 no longer suitable for use in Europe, and, thus, it was replaced by EN 17141. Now, there is a push to accept EN 17141 as the international standard, as it is significantly more up to date and applicable than EN ISO 14698. EN ISO 14698 was last […]

After 17 years of no revisions, a formal vote in 2019 replaced EN ISO 14698 with EN 17141 in Europe. Shortly after, confusion ensued. While CEN/TC243 (the technical committee in CEN) had found EN ISO 14698 obsolete and replaced it with a new guidance (under a new number, to avoid confusion), old versions still existed […]

EN 17141 Cleanrooms and controlled environments – Biocontamination control is a relatively new European standard, introduced in 2020, that establishes and demonstrates best practices to control airborne and surface microbiological contamination in controlled environments, such as cleanrooms. This standard applies specifically to European cleanrooms in the pharmaceutical and biopharmaceutical, hospital, and food industries, as identified […]

In 2017, GMP released a draft update to Annex 1, which received a lot of feedback. Now, GMP has released a finalized version of the updated Annex 1, which addresses many of the concerns and questions raised about the draft version. The largest changes and shifts in this document are found in the increased focus […]

The European Union (EU) Good Manufacturing Practice (GMP) for Medicinal Products for Human and Veterinary Use – Annex 1, commonly referred to as GMP Annex 1, was originally published as a draft in 2017. This draft left many people operating in the pharmaceutical industry wondering at some of the proposed changes to the regulations that […]

If you use compressed gasses in your cleanroom, ISO 8573 is an important set of guidelines and regulations for your cleanroom, specifically ISO 8573-1:2010. This set of guidelines is maintained and governed by the International Organization for Standardization (ISO), an international, non-governmental organization dedicated to creating worldwide standards for a variety of industries. ISO standards […]

Good Automated Manufacturing Practices (GAMP). GAMP is both a technical subcommittee of the International Society for Pharmaceutical Engineering (ISPE) and a set of guidelines for manufacturers and users of automated systems in the pharmaceutical industry. ISPE is the world’s largest not-for-profit association serving its members by leading scientific, technical and regulatory advancement throughout the entire […]

If you know us, then you know that clean air and water is our passion in life. But what happens when you cannot prove to the regulatory authorities that your air and water is clean? Cleanrooms and monitoring systems generate a lot of data. In an 8 hour shift, as many as 5,000 individual count […]

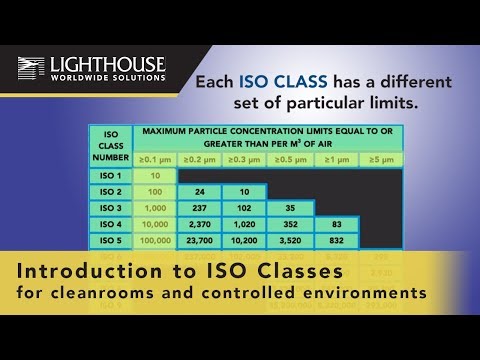

ISO 14644 is a standard for cleanrooms that was developed by the International Standards for Organization (ISO). The ISO has been in existence since 1947, after 65 delegates from 25 different countries met to discuss its future the previous year. They saw the need for a non-governmental body whose sole job it was to determine […]

What is the biggest villain in the contamination control and cleanroom world? Particles. Contamination. This contamination can cause yield and financial loss, delays, frustration, and physical threats to the end user. It is something that should be avoided wherever possible. To minimize contamination risk in your cleanroom, you first need to understand what contamination control […]

The following questions will help you ask the right questions when implementing a system thatadheres to 21CFR Part 11. It is important to satisfy the requirements of this FDA code in order toenable Data Integrity and Data Traceability as well as the electronic signatures that verify the dataas original, valid, and accurate

21 CFR Part 11 outlines the federal requirements that help to ensure that electronic records are trustworthy, reliable, and generally equivalent to paper records and handwritten signatures executed on paper. 21 CFR Part 11 has 10 chapters over 3 subsections. These subsections are General Provisions, Electronic Records, and Electronic Signatures.

Water is one of the major utilities used by the pharmaceutical industry. Different grades of water quality are required depending on the different pharmaceutical uses. Control of the quality of water, in particular the microbiological quality, is a major concern and the pharmaceutical industry devotes considerable resources to the development and maintenance of water purification […]

We are all too well aware of the adverse effects of particulate matter contamination within parenteral injectable pharmaceutical products and the consequences for patient safety. Here, particulate matter refers to the small, sub visible particles. The United States Pharmacopoeia, USP <788> provides two tests for detecting such particulates: light obscuration and microscopic assay. Both are […]

Good Manufacturing Practices (GMPs – sometimes referred to as Current Good Manufacturing Practices or CGMPs) are federal regulations set by the FDA to cover how pharmaceuticals and food products are manufactured. They are guidelines taken for granted by many consumers – they assume what they put in their body will have been safely produced – but […]

KNOWLEDGE CENTER

SERVICE & CALIBRATION

SUBSCRIBE

Get the scoop on new products and the latest tech papers, webinars and more…