So you’re going to classify your cleanroom. But what cleanroom classifying tools can you use that will make the process painful and easy?

First things first, let’s define cleanroom classification.

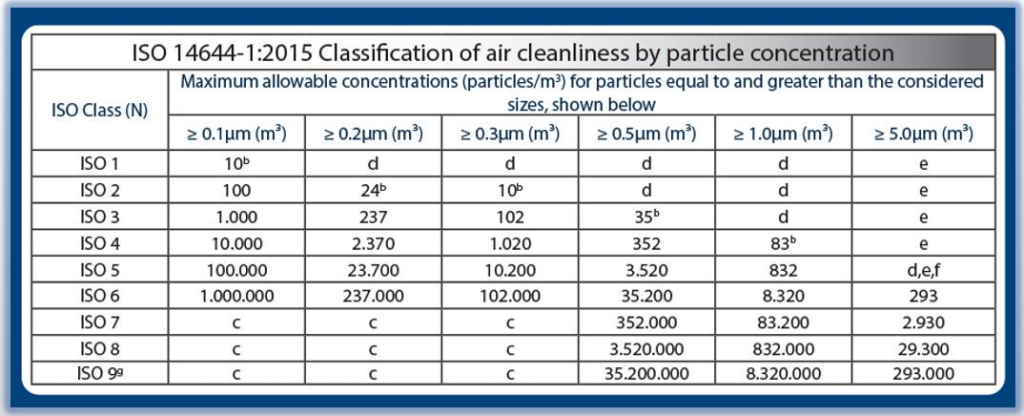

The International Standards for Organization (ISO) is one organization that sets cleanroom classifications. ISO is a non-governmental agency that sets standards in a number of industries. These standards are widely respected throughout the world.

In the US, there is another set of classifications. The Federal Standard 209 (FS 209) was established in 1963 by the Institute of Environmental Sciences and Technology (IEST). This set of classifications also has a range of options. Their classifications range from FS209A to FS209E.

ISO classifications are defined by ISO 14644-1, which matches the requirements for FS209. We often see these classifications as a requirement, but in the world market, we tend to refer to ISO standards.

The ISO standards classify rooms in 9 categories. ISO 1 defines the cleanest of cleanrooms, in relation to the number and size of particles, whereas ISO 9 defines normal room air.

So when it comes to cleanroom classifying, it is important you do it right. You need the right tools to count your particles in different areas to get the numbers you need. After you classify your cleanroom, you need the right tools to keep it at your classification level. Both classification and ongoing monitoring are fundamental to a cleanroom contamination control strategy. [1]

What Are Particle Counters?

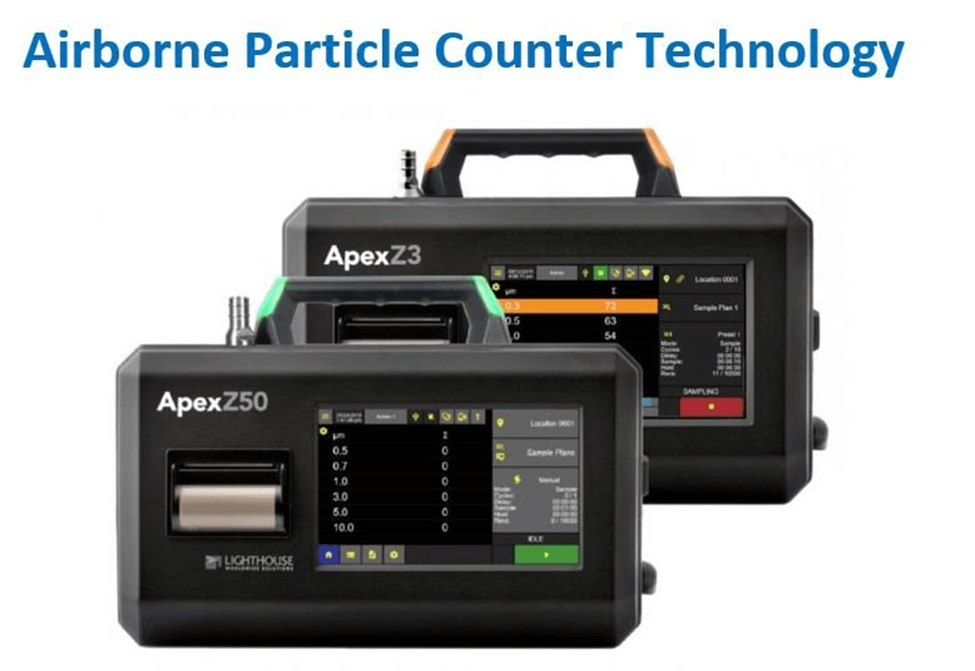

Airborne particle counters are instruments that count the number and size of particles in a given space. There are three primary types of particle counters: remote, handheld, and portable. Remote particle counters are small and semi-permanent. They work well as a part of the infrastructure. Handheld particle counters are small and portable with a low flow rate, so they are often slow. Lastly, portable particle counters are the larger (but ergodynamic) and fast option that can be moved around the cleanroom. They are the most popular option.

Your selection criteria for your particle counter should consider the exact specifications of the instrument based on your needs. This includes how small of a particle it can detect, flow rate, ease of use, and more.

Because this is a major investment, we recommend examining your supplier. Take a look at their track record and service abilities. While the instrument really matters, the support behind it makes or breaks your successful classification.

Classifying your cleanroom requires using a calibrated instrument. Particle counters require annual calibration. The proper calibration for airborne particle counters follows ISO 21501:2018 according to ISO 14644-1:2015. Your instrument might also need sensor cleaning, optic parts replacement, occasional laser replacements, and other general maintenance for regular wear and tear.

What To Look For In Your Particle Counter

With that in mind, what questions exactly should you ask when considering a particle counter? We have a few in mind!

- Is the airborne particle counter able to be calibrated according to the ISO 21501:2018 standard? What about ISO 17025 accreditation?

- Does the supplier calibrate the unit on-site?

- Does the supplier have a service level agreement contract?

- How easy is it to program the user interface?

- How simple is it to run ISO and GMP reports?

- How fast can it sample 1m³ volume of air (flow rate)?

- How many particle channels does the unit support?

- Are the sizes of particles monitored appropriate for your application?

- Are you able to disinfect and easily wipe down the machine?

- Is the particle counter designed to be free from particle traps?

- How heavy is the unit? Is it truly portable?

- How large is the unit? Could it fit into an isolator or LAF cabinet easily?

- How long does the battery last?

- What is the recharge time?

What Are Air Samplers?

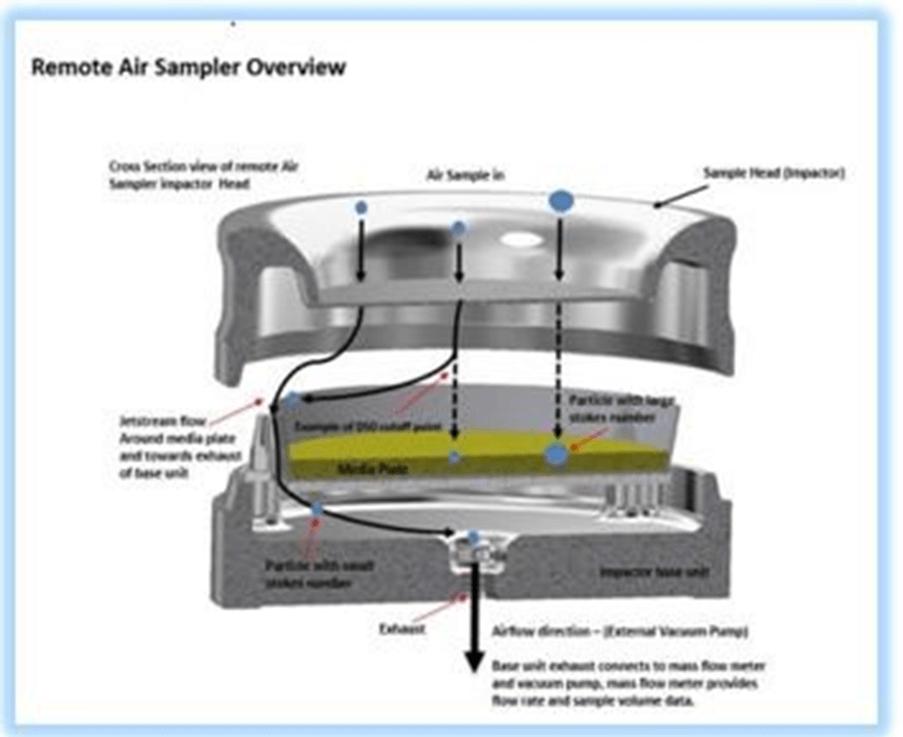

Once you’ve classified your cleanroom, you can use an air sampler as a monitoring tool for your cleanroom. Air samplers will determine if viable particles are present. While airborne particle counters use something called light scattering to determine size and number of particles, air samplers work in a different way.

They draw in air and run it through or over a media that can identify if the particles are viable or not based on the reaction.

We recommend using ISO 14698 as a guide to assist you selecting the right air sampler for you. Air samplers use a critical factor known as the d50. This means that 50% of the particle diameter will impact the media. The other 50% is, instead, influenced by the air path of the sampler. This is also called the cut-off point. ISO 14698 expects the d50 to be as low as 1µm.

The d50 is one important factor, but the unit also needs a HEPA exhaust filter.

Unfortunately, many air samplers do not have a HEPA exhaust filter or meet the appropriate d50 threshold.

What To Look For In Your Air Sampler

While a HEPA exhaust filter and appropriate d50 are important considerations, what are some other things to look for?

- Just like with particle counters, supplier support is crucial. Will they calibrate on-site?

- Is there a service-level agreement contract?

- How simple is it to program the user interface?

- Is it easy to set-up samples?

- Is the unit able to load differing media plates from different suppliers easily?

- Is the unit intuitive to use?

- How fast can it sample 1m³ volume of air (flow rate)?

- What is the d50 cut-off point (resolution)?

- Is there a HEPA exhaust filter that prevents recirculation of the sample?

- Is the base easy to detach and sanitize?

- Is the particle counter designed to be free from particle traps?

- How simple is it to load the 90mm media plate?

- How long does the battery last?

- What is the recharge time?

Classifying Your Cleanroom: Particle Counters vs Air Samplers

So when it comes to classifying your cleanroom, do you need an airborne particle counter Well, the answer might be both! Airborne particle counters are powerful machines for continuous monitoring, but they cannot tell viable particles from nonviable particles.

On the other hand, that is the purpose of air samplers. They often work best in conjunction with an airborne particle counter, though. Air samplers can take longer to produce results and might not be able to detect the smaller particles the counter catches.

If your cleanroom classification requires you to detect viable particles, you should use both a particle counter and an air sampler. Your particle counter will continue to serve as a powerful tool for continuous detection.

Whichever tools you need for classification, remember that the supplier is just as important as the unit itself. A supplier who stands behind their units and offers on-site calibrations, service-level agreement contracts, ongoing support, and general maintenance will get you a lot further than a hands-off supplier.

Now, it does help when a supplier offers industry standard-setting airborne particle counters, like the ApexZ50, and air samplers, like the ActiveCount100H.

If you’d like to see either trend-setting, goal-reaching units in action, let us know. We’re happy to offer hassle-free consultations.